Increasing The Size Of Solar Wafers – What To Expect?

powernsun2023-11-14T18:43:52+04:00Increasing the size of solar wafers is becoming an attractive approach for solar panel makers in increasing the power output of the panels. In fact, this has been a trend in the solar industry since 2010 and this shift to a larger solar wafer format is expected to grow faster. This trend has become very notable in recent days and it has its roots in Asia and it continues seamlessly. Manufacturers across the world are eager to come up with new wafer sizes that would help customers achieve a lower levelized cost of power and a higher ROI.

Understanding the Size of Wafers in Solar Panels

In the emerging and competitive solar market, manufacturers are looking at the possibilities of bringing out solar panels that could enhance the power output. To be very precise, the last decade is truly a golden era for solar-powered products. The latest innovative approach of adopting increased solar wafer size is perceived as the best way to attain the industrial expectations of improved output.

Manufacturing is a crucial concern in any value chain, the same is true with solar panel production. The three stages of solar panel making involve:

- Wafering

- Cell processing

- Module making

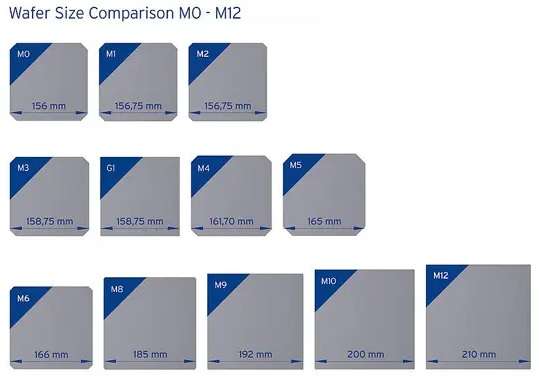

Among the above stages, wafering is subject to continuous optimization in regard to a larger format. Some of the standard wafer sizes used in solar cell manufacturing are M1, M2, M3, M4, M5, M6, and M12.

The manufacturers started using M0 wafers types in modules with the size of 156mm X 156mm. It has been regarded as the dominant and quite popular in the industry for nearly a decade. Subsequently, it was replaced by variants of M2, M3, M4, M6, and M12 with solid solar cell panels of 60, 72, and 144.

The wafer is the power-generating component of solar modules. They account for nearly 40% of overall module costs. When it comes to crystalline solar cell production, the wafer is the starting material. It is about 200 µm thick.

There are endless developments with the new wafer sizes. Typically, the wafer size is measured in inches. However, in recent days, millimeter measurement has been used to indicate the size of wafers.

Polysilicon and silicon wafers are the predominant wafers in the solar market. Monocrystalline and Multicrystalline are also having their part in fulfilling the demands. Used in solar cells, wafers are textured so that they make a rough surface, aimed at increasing their efficiency.

Why is solar wafer size getting bigger?

Those days when the world sticks to standard dimensions no longer exist. Manufacturers of the modern world are exploring new methods to fulfill the demands of the solar market intended to maximize the available active space. The adoption of solar systems and awareness towards switching to solar is pushing the demand for solar wafers.

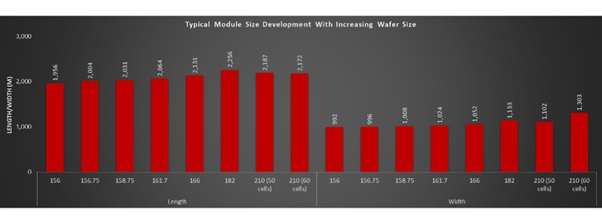

The major reason to look into increasing the size of solar wafers is to attain a lower cost per watt ($/W). The bigger the solar wafer, the more vast the covered areas of the solar panel surface. Eventually, it will result in reduced system cost (Balance-of-system) and accelerated power output.

If you look back 40 years ago, the increase in wafer sizes had been noted with consistency and after the 2000s, it has grown to 125 mm.

Increasing the size of wafers not only improves the module power but also reduces the thickness of the wafer. One of the core attributes of the wafer is its thickness. With reduced wafer thickness, the manufacturing cost is also reduced.

Considering the end customers, the benefits that can be gained from increased-size solar wafers are more output power per module, requirements of fewer modules for the surface, and reduced related equipment such as brackets, junction boxes, cabling, and more.

To put it simply, wafer size matters in the PV industry. As said, since the wafer is the power-producing element in a solar cell, increasing the wafer size increases the power output. Ultimately, the result you can get is a lower levelized cost of electricity and a better return on investment for solar projects.

Explore high-efficiency and High-performance PV modules from Longi

The world’s leading Chinese solar manufacturer Longi is well-known for its Silicon Wafers, an innovative and new evolution of products – Hi-MO 6 and Hi-MO7 Product Family.

Hi-MO7

Hi-MO 7 from the world’s popular LONGi is the latest generation of high-efficiency modules exclusively designed to suit the utility market. The product adopts n-type HPDC technology and it comes in a standard size of M10-72c 2278×1134mm. The mass production power of the modules can reach up to 580W, along with a conversion efficiency of 22.45%.

Highlights of Hi-MO 7:

- Excellent power generation performance

- Product reliability

- Perfect for applications with high temperature, high albedo, and limited space

- Increased installation capacity

- Power increase of up to 4.5%

- Annual degradation rate – up to 0.4%.

- Superior power temperature coefficient – -0.28%/℃.

Hi-MO6

LONGi Hi-MO X6, a new product family from Longi, is quite known for its efficient HPBC cell technology. The products boast of the characteristics of aesthetics, reliability, efficiency, and intelligence. These are the modules best suitable for distributed power stations.

Depending upon the functional characteristics and application scenarios, they are divided into four series:

- Explorer

- Scientist

- Guardian

- Artist

Highlights of Hi-MO6

- Unique high-efficiency HPBC cell structure

- Efficiency of HPBC cells exceeds 25.5%.

- Aesthetic Appearance

- Outstanding Performance

- Market-leading Reliability

- Intelligent optimization through pre-made optimizers.

Switch to bigger wafers with Powernsun

Powernsun believes that it has a key role in bringing the latest developments in the solar industry to those who seek to make the switch to solar. Since the benefits of larger solar wafers are very obvious in the solar market, we strive to meet the emerging demands of the trending larger solar wafers from the globally leading brands. We take pride in supplying you with the high-powered solar modules to the market.