Optimizing Rooftop Solar Power Generation

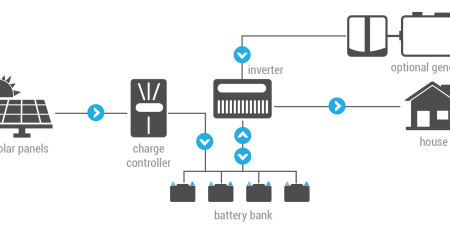

Depending on the scale of the project, maintenance is important to realize the tip goal of reducing utility costs and generating maximum clean energy. The scope of labour under every project’s operations and maintenance differs and is determined after surveying the project. during this article, we are going to discuss how our team evaluated a project in Dubai and offered scheduled operations and maintenance services to optimize the solar PV system’s generation capacity.

Solar Power recently resumed operations and maintenance services of a 1MW solar pv plant for a serious technology consultant firm in Dubai. The organization had multiple rooftop solar PV systems founded across its office campus. Since the solar PV system was the most important energy driver for his or her office space, it had been important for them to maximise their solar power generation and impede their utility costs. With the system being over 3 years old with limited maintenance, our engineer surveyed the project and proposed the subsequent scope of labour.

Manual Module cleaning activity

Mentioned multiple times, one in all the foremost causes of low power generation is irregular panel cleaning. As rooftop solar panels tend to accumulate dust and bird droppings, it disallows the solar PV system to come up with power at its full capacity. In this situation you avoid, our team proposed a manual module cleaning activity once every week to attain the targeted generation.

Performance monitoring

Daily monitoring of components like DC strings, SCB, ACB, Inverter, Data logger, and SCADA parameters to observe the Performance Ratio (PR) of the system. Upgrading of the firmware of Inverter & SCADA. As component failure could lead on to system failure, regular monitoring is required not only to test the health of the system but to also note if the required solar power generation is achieved.

Preventive Maintenance

This step is very important to require preventive measures supporting factors like conditions of the roof, weather, surroundings, component quality, etc. Solar installers with proposed regular checking of strings, lugs, insulator, cables connections associated with panels, SCB, ACB, and inverter. Enchanting such measures reduces system downtime and improves the efficiency of the system. Our team also ensured that everyone’s services and precautions were taken without hampering the manufacturer’s warranty. These measures enhance the sturdiness and lifetime of the system.

Corrective Maintenance

The corrective measure helps troubleshoot any faulty equipment as soon as possible to scale back system downtime. This also includes replacing any worn off components. As a solar company in Dubai, we ensure quick deployment of an engineer onsite.

Durable structure

To ensure a well-made structure, our team implemented structure trenching with proper torquing tools and listed torque table. When labour involves grass cutting, cable trenching, and housekeeping activity to stay plant safe and secure from reptiles which may cause severe damages to HV lines.

Audit & Breakdown report

A quarterly plant health analysis to observe its projected vs actual performance. This will be determining service report improvements, measures taken to implement safety in plant and electrical equipment handling, checking the performance ratio of the plant, etc.

Safety Training

Since the system is accessible on multiple rooftops, engaging at height training would be provided on a monthly basis. Likewise cleaning the solar panels and everyday maintenance activity training would be provided before starting work.

Leave a Reply