Difference Between Armoured And Un armoured Solar Cables

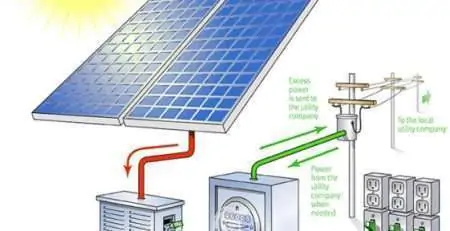

powernsun2023-12-14T13:09:21+04:00Renewable energy sources are grasping the attention of nations across the world. Since it is the optimal way to generate power without impacting the environment, there are lots and lots of innovations introduced in the renewable industry, especially solar. One of the crucial elements of solar power systems is cabling. Solar cables are specialized electrical cables that are useful in interconnection in solar power systems. These cables connect solar panels to other solar panels and system components such as batteries, inverters, charge controllers, and electrical components.

The choice of the right solar cables plays an essential role in the seamless, efficient and reliable power transmission. In this blog, let us explore the differences between armoured and unarmoured solar cables.

Armoured Solar cables

Armoured solar cables come with an extra layer of protection intended to protect them from physical damage and the environment. Typically, this additional layer is built using plastic or metal and it surrounds the cable core. The armoured cables can be made up of various materials such as copper, aluminium, etc. Armoured solar cables are packed into metal sleeves and processed into a solid combination that you can bend.

The armour layer of coax cable is a kind of foil wrap that comes with flexibility and ribbed-like corrugated metal. A flooding compound is present both inside and outside of this wrap and is aimed to avoid moisture entering into the cable. The internal structure of the 4-core armoured cable generally contains a variety that safeguards the cables from damage.

Applications of armoured solar cables

- Armoured solar cables are widely used in buried environments, cable trench laying or direct burial requirements.

- Armoured Cables are installed in locations that can be exposed to mechanical damage. This covers the environment like on the outsides of walls.

- These cables are mainly installed for temperature measurement, metallurgy, machinery manufacturing, signal transmission and special heating in the chemical industry, power generation and scientific experiments.

Unarmoured solar cables

Those cables without steel armour protection are referred to as unarmoured solar cables. Also called non-armoured cables, there are numerous conductors or groups of conductors twisted together in these cables to form a rope-like cable. Each group of conductors will be insulated from each other. They often twisted around a central and highly insulating covering.

Applications

- Unarmoured solar cables are majorly used for control systems

- High-quality unarmored cables are useful in fulfilling the needs of power transmission.

Differences between armoured and unarmoured solar cables

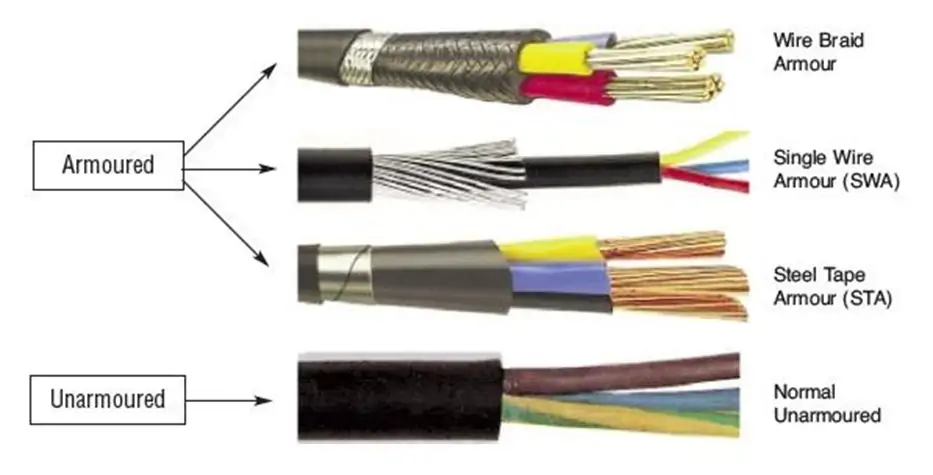

Structure

Armoured – The additional outer protective layer of armoured cable is typically made of steel tape or steel wire, and it protects the cable from external mechanical damage. This extra protective layer also safeguards the cables against bites of rats and termites. The bending radius of the armoured cable is large.

Non-armoured – The major thing that makes armoured solar cables different from unarmored cables is the presence of an additional external protective layer.

Cost

Armoured – Expensive when compared to non-armoured cables.

Unarmoured – They are less expensive as they do not need any additional materials or manufacturing processes for the additional protective layer formation.

Why should you prefer armoured solar cables over non-armoured cables?

So, as we see, the major difference between the armoured and unarmoured solar cable is the presence of an additional protective layer of metal reinforcement. Though these two cables are different and vary in their applications, yet, the armoured solar cables are preferred in most cases due to their strength.

The mechanical protection layer of armoured cables can be added to any cabling structure and this helps in increasing the mechanical strength of the solar cables. Ultimately, they help achieve improved erosion properties and are best suited for areas that are exposed to mechanical damage and erosion.

Since the armoured solar cables have extra layers, they enrich tensile strength, and compressive strength, eventually leading to extended service life. The armoured cables possess resistance to external forces.

Conclusion

The world is rapidly making the switch to environmental choices and solar power is inevitable among that. When it comes to solar cables, they are not only eco-friendly choices but also they are recognized for their durability of up to 30 years. Solar cables come with a long service life and offer reliable performance over an extended period.

As mentioned above in the comparison, armoured solar cables with the additional protection layer are designed to withstand unique harsh requirements, ensuring superior energy transmission. The 4-conductor armored cable delivers unparalleled protection from physical damage making perfect choice for any power transmission in hazardous situations.

Buy APAR’s E-Beam Irradiation Technology Solar cables

Powernsun is delighted to bring you the Electron Beam irradiation armoured solar DC cables from APAR that are best known for their outstanding performance in demanding applications and harsh environments. This E-beam irradiation technology from the brand ensures improved cross-linking and polymer modification for the solar cables, still, the process doesn’t release any harmful chemical by-products. The cables are highly capable of withstanding high temperatures of up to 105˚C, safe, and are ideal for high-end and safety projects.