Time, Cost and Quality Dimension of Solar Projects

When analyzing the emergence of rooftop solar projects, it is vital to understand that, for sustained growth to take place along the value chain, the time required to turnaround a project plays a key role. Meaning that, as the rooftop solar market grows in the wider MENA region, solar installers will be pushed to deliver projects in half the time, at half the cost and double the quality at which they are currently being delivered, irrespective of their size and nature. Therefore, one must look at the associated time, cost and quality dimension of a project and ensure preparedness.

Elements of a project lifecycle:

There exist three major elements between the time a contract (between solar contractor and customer) is finalized and actual connection of the solar plant to the grid:There exist three major elements between the time a contract (between contractor and customer) is finalized and actual connection of the solar plant to the grid:

1) Availability and cost of resources from different suppliers

2) Time required to install and commission the plant

3) Quality of installation

Currently, 60-70% of the time required to complete a project is allocated to organizing the supply chain, especially for small to mid size solar projects. This involves creating a master plan, pricing different components, negotiating with manufacturers, paying manufacturers and eventually, initiating a movement of goods.

The balance 30-40% is allocated to the actual installation of the plant. If this whole life cycle of pricing, procuring and installing components for solar plants is managed better, the duration of the life cycle can be drastically reduced, thereby decreasing the supply chain cost and lowering project turnaround time. Achieving standardization across the supply chain is not a foreign concept because it already exists in other major industries. Within the auto industry for example, product standardization, demand consolidation and efficient inventory management have led to faster development and delivery of cars.

Click here to read about solar panel price in Dubai,UAE

How can we achieve these efficiencies?

Supply Chain Management

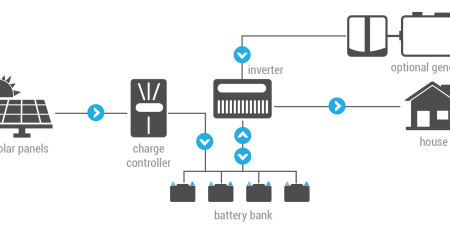

Currently, the majority of components used in solar projects can originate from 10-15 suppliers, sometimes even more. Using the concept of master planning and consolidation, one entity takes on the responsibility of negotiating with all the different suppliers, thereby allowing the contractor to deal with only one or two entities that meet the required specifications and quality parameters. This calls for an overall understanding of supply chain management, which requires knowledge on the movement of material goods, of information and of money.

The objective is to synchronize the supply chain with required

visibility and alignment for larger gains, which can achieved faster with the minimum required number of supply chain participants. This can also ensure a required trust, transparency and totality in the system. This entire process must be conducted in the most cost efficient way possible.

Demand Aggregation

It is another concept which can be used appropriately to trim down the excessive fat accumulated across projects due to their sizes – the smaller the size of a project, the higher the cost per kilowatt. These higher costs can be attributed, not only to material costs but also to fixed costs that don’t necessarily vary according to size, e.g. logistics, custom clearance, cost of information sharing, system optimization, inventory build-up, etc.

If there are three separate 1 MW projects, it might make more sense to aggregate them into one project of 3 MW to help reduce costs. The industry benefits when consolidated demand management is shared across the system. International studies in similar industries suggests an overall cost reduction of 3-5%. When demand aggregation is managed through an online system, it achieves its goal of cost reduction much faster.

Click here to read about solar panel suppliers in UAE

one stop shop solution:

When the concepts of Demand Aggregation and Supply Chain Management are clubbed together, they essentially form a “One Stop Shop Solution” that creates a platform from which many of the solar plant components are sold. They support the supply chain of solar projects with the aim of reducing overall project costs and maximizing customer value. In general, looking at solar components today, 55-60% of the project cost is attributed to the panels, 10-12% to inverters, 12-15% in balance of system (BOS) materials and another 15-18% in EPC margins, installation costs etc. Contractors don’t need to approach and deal with different entities at once, they can simply capture this demand using the platform offered by the demand aggregator.

Efficiencies like this will exist when there is general alignment within the market on the key technologies being used in solar plants and a good level of transparency within the local supply chain.Using these two principles, one can achieve up to 30% reduction in project turnaround times and 3-5% in cost reduction simply by having a well-managed and trustworthy supply chain. Looking ahead, the industry will gain when its members start looking at co- operation, collaboration and consolidation.

Leave a Reply